Future or FAD?

The shift from traditional supply chains to digital supply networks marks a significant evolution in how companies manage the flow of goods and information.

By leveraging new technologies and consulting expertise from firms like Gryphon Citadel, businesses can achieve a resilient, responsive, and efficient supply chain that fits the future’s challenges and opportunities.

This transformation enhances operational efficiencies and drives competitive advantage in an increasingly complex and interconnected marketplace.

Supply Chain Evolution

Traditional Supply Chain Issues

Traditional supply chains are characterized by a series of linear steps involving product development, planning, sourcing, production, and distribution. Each step is distinct and often managed in silos, which can lead to inefficiencies such as:

Visibility – Lack of real-time data flow between stages, leading to inventory mismatches and overproduction.

Inflexibility – Difficulty in adapting to changes in demand or supply.

Slow Response Times – Increased time to market due to linear and sequential processes.

Furthermore, corporations typically face several issues with traditional supply chains, including:

Supply Chain Disruptions – Vulnerability to global disruptions such as natural disasters, trade disputes, and pandemics.

High Operational Costs – Inefficiencies in logistics and production that inflate costs.

Quality Control Challenges – Ensuring product quality across global supply chains can be complex and resource-intensive.

Improvement Opportunities

To address the challenges described above, companies can:

Implement Lean Manufacturing – Reducing waste and optimizing processes to enhance efficiency.

Adopt Just-in-Time Inventory – Minimizing stock levels to reduce holding costs and increase turnover rates.

Enhance Supplier Collaboration – Build stronger supplier relationships to improve material quality and delivery timelines.

Past Influences of Technology on Supply Chains

Previously, technology integration in supply chains was limited to automating manual tasks and improving communication through electronic data interchange (EDI) and enterprise resource planning (ERP) systems. These technologies provided foundational support but often struggle to deliver real-time insights or drive end-to-end supply chain optimization.

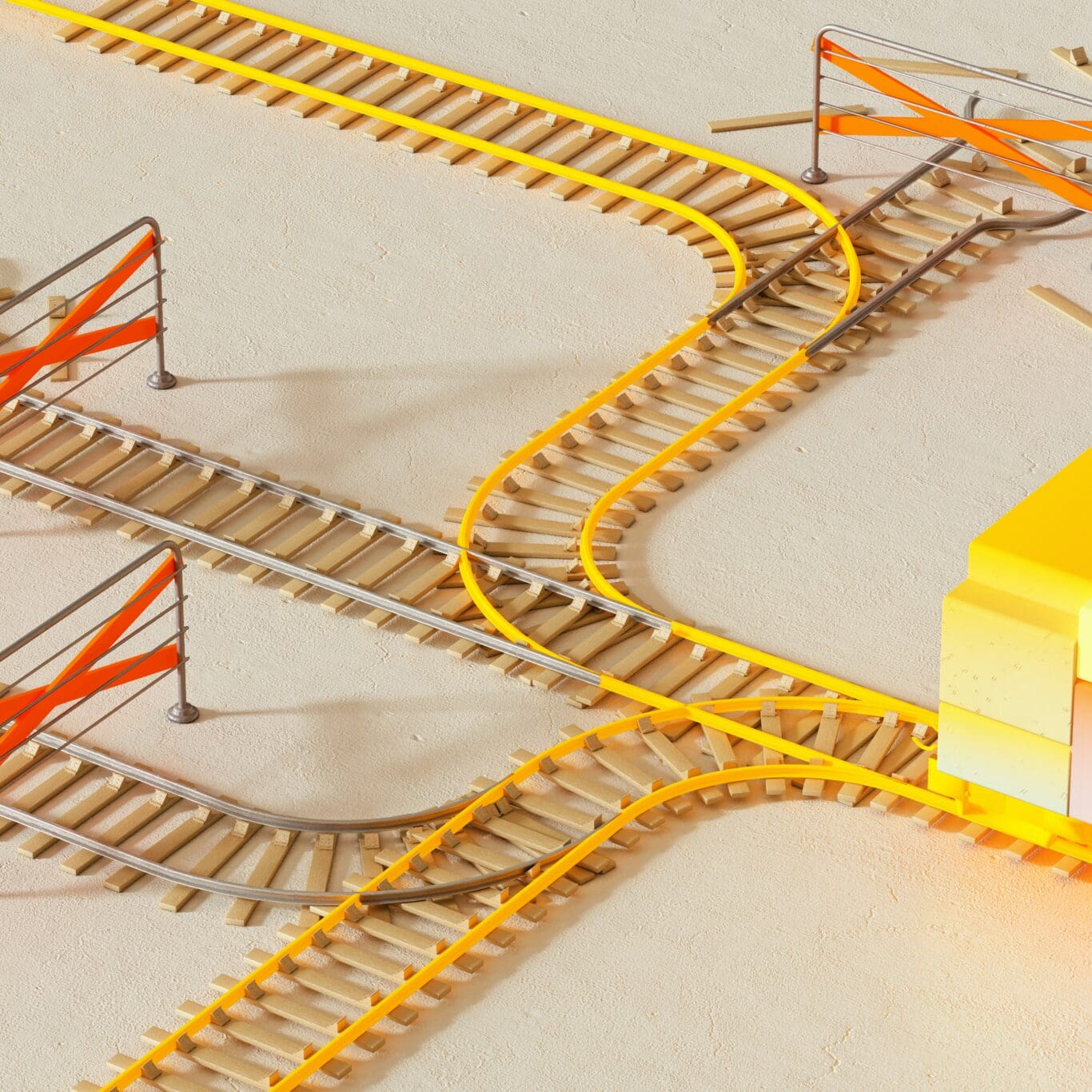

Emergence of Digital Supply Networks

Digital supply networks (DSNs) are revolutionizing the market by integrating advanced digital technologies:

IoT and Sensors – Real-time tracking of goods and assets to improve visibility and predictability across the supply chain.

AI and Machine Learning – Enhancing decision-making by predicting market trends and responding proactively to supply chain risks.

Blockchain – Increasing transparency and trust through secure, immutable records of transactions and product provenance.

The Digital Supply Network transforms the linear process steps of traditional supply chains into a dynamic, interconnected system that is more responsive and adaptable to the changing market environment.

These interlinked networks leverage technology to create a synchronized chain that anticipates future demands and smoothly adapts to disruptions.

How we can help

We facilitate transformation and play a pivotal role in transitioning companies from traditional supply chain mechanisms to advanced DSNs through:

Assisting companies in understanding their current supply chain operations and identifying digital opportunities.

Guiding the integration of IoT, AI, and blockchain to streamline operations.

Ensuring that digital transformations are adopted across the organization, aligning with overall business objectives.

Helping organizations implement and sustain changes through continuous monitoring and adapting to new emerging technologies.

The shift from traditional supply chains to digital supply networks marks a significant evolution in how companies manage the flow of goods and information.

By leveraging new technologies and consulting expertise from firms like Gryphon Citadel, businesses can achieve a resilient, responsive, and efficient supply chain that fits the future’s challenges and opportunities.

This transformation enhances operational efficiencies and drives competitive advantage in an increasingly complex and interconnected marketplace.